Thank You for Making this Conference a Huge Success!

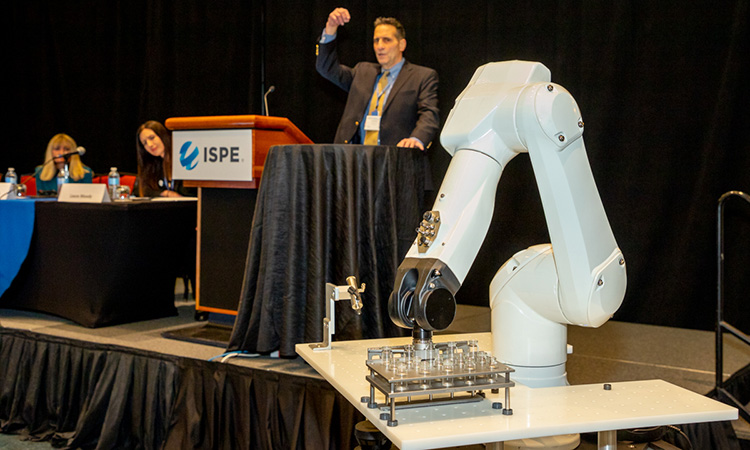

The 2020 ISPE Aseptic Conference delivered engaging presentations and case studies on cutting-edge topics with many opportunities to network and gain insights from top industry professionals. Check out the content below to get insights from the conference.

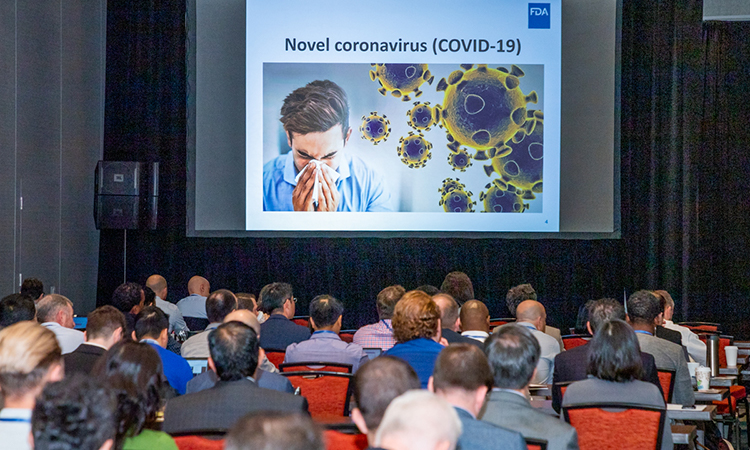

Hear from Alonza Cruse, Director, Office of Pharmaceutical Quality Operations, FDA/ORA, as he highlights some of the FDA’s actions and activities in response to the Coronavirus (COVID-19) at the 2020 #ISPE Aseptic Conference.

Umit Verma, Vice President, Commercial Manufacturing, Iovance Biotherapeutics, Inc., offers his expert insights during his presentation Planning for The Unknown – Autologous Cell Therapy Scale Out Planning at the 2020 #ISPE Aseptic Conference.

Having had a long career history with the FDA, David Doleski, Compliance Head for Biologics Quality Operations, Sanofi, provided his insight into the mindset of a regulator during his keynote presentation How Perspectives Change: From Regulator to Regulated at the 2020 #ISPE Aseptic Conference.

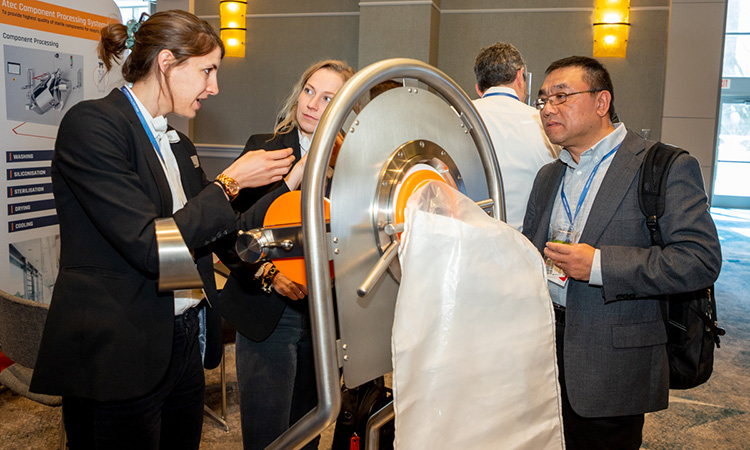

Hear from Laura Moody, Product Manager, Primary Packaging, NA, Syntegon, as she answers a question that came about from her presentation Adapting to Standardization of Extractables Testing for Single-Use Components at the 2020 #ISPE Aseptic Conference.

Having had a long career history with the FDA, David Doleski, Compliance Head for Biologics Quality Operations, Sanofi, provided his insight into the mindset of a regulator during his keynote presentation How Perspectives Change: From Regulator to Regulated at the 2020 #ISPE Aseptic Conference.